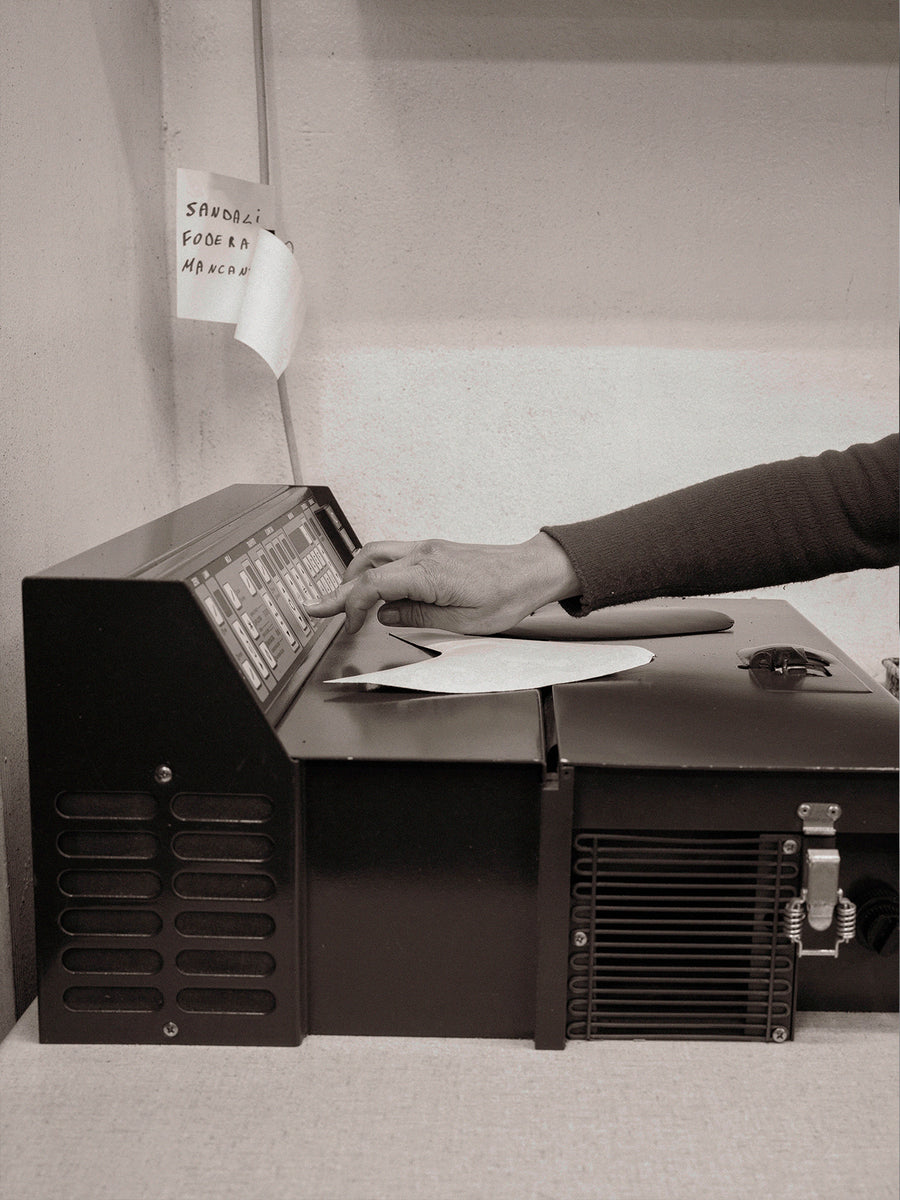

To create awareness within our community about the stories behind our pieces, we commissioned a photo essay that offers a glimpse into what daily life looks like in our factories in Tuscany. To accompany it, we spoke to our founder Luisa Dames about the need to rethink our relationship to fashion, what Aeyde is doing to reduce its carbon footprint, and what we can do to be more conscious consumers.

Words: Charmaine Li

Images: Studio Mare

Can you take us back to Aeyde’s beginnings? What did you set out to change in the fashion industry when you started the brand?

When I started Aeyde in 2015, I couldn’t find any shoes that were high quality, but affordable, and had the kind of modern design I wanted to wear. As a customer, the only offerings I found were either cheaper, lower-quality brands that were often produced under not-so-sustainable circumstances or luxury designer shoes that cost a fortune. Back then, I just wasn’t able—or willing—to spend so much on a product, so I would always wait for sales periods to buy them at a discount, which felt quite wrong to me since I knew how much effort went into creating a product. So, I really wanted to create a high quality product using modern design language and offer it at an accessible price point. And that’s what we do today, we’re democratizing good quality and design so that people can afford to make better fashion choices.

How would you describe Aeyde’s philosophy on fashion?

I wanted to create a product that lasted from day to night, that you could wear to work and then to drinks with friends afterward, and that could be worn season after season. It was really important to me that we designed products the customer needed and that could become everyday staples.

In terms of your design approach, what are some of the brand’s values that inform this process?

Essentially, we want to create designs that are versatile enough that you can still wear in 20 years’ time. At the heart of our brand is the belief that good design is long-lasting, so we want our pieces to have longevity and transcend trends. Designing for this is a lot about sourcing the best materials and studying shapes and forms that are timeless.

It’s like when you go to a vintage store, or look through your mum’s closet, and find a piece that was designed decades ago but, still, there’s something about the material or silhouette that feels iconic enough that you can easily integrate it into your wardrobe today. Or if you look at an Eiermann chair, for instance, it gets more beautiful with use and acquires a patina that gives it character as it ages. I think it’s the same with shoes, if you source high quality leather materials and construct them into classic shapes with slight modern details, the pieces get better with time.

The word 'sustainability' can mean many things. What does becoming more sustainable as a fashion brand mean to you?

For me, sustainability is a tricky word because any company that creates new products for consumption is inherently taking part in an unsustainable process. Personally, I think it’s more about responsibility than sustainability. And being responsible as a fashion brand means considering the impact of our supply chain and finding meaningful ways to reduce our carbon footprint.

Can you expand a bit more on what it means to be a responsible brand?

It’s really about examining each step along the entire supply chain and identifying improvements. For example, if we look at the first part of our supply chain, one step we took was to source all of our leathers sustainably in Europe and to use byproducts from the food industry. We also started looking into different alternatives to leather, such as pineapple leather, to see whether we can incorporate new materials into our products in the future.

Then there’s the packaging part, it’s so common to see shoes arrive wrapped in a lot of plastic. It’s quite shocking to me how much plastic is used to protect the products actually, so we decided to remove plastic from all of our packaging and invested in 100% biodegradable materials for this. Of course, this comes at a cost for us but we think it’s necessary. Another thing we do to minimize waste is produce limited quantities of items and then see what the customer demand is like for styles instead of overproducing like many other fashion businesses.

Of course, as an e-commerce company, we have a carbon footprint, so it’s our responsibility to look into reducing and offsetting that, which is something we’re still working on right now. So for me, being a responsible brand means investing in processes that are better for people and the planet, rather than prioritizing profits.

When producing a collection, where does Aeyde source its materials? How do you select manufacturing partners?

All of our products are handmade in Italy. It’s really important that we produce everything locally in Europe, close to our headquarters in Berlin. I’ve worked at other places before where production took place further away in countries such as India or China and I think there are a lot of advantages to having that side of things nearby. It ensures transparency throughout the entire process.

When it comes to sourcing materials for each new collection, we start by turning to our small network of local suppliers that we have close relationships with. The leathers we want to integrate into a season are produced in our hand-picked tannery, so we know exactly where they come from and how they are treated. Again, all of our leathers are byproducts from the local food industry. Then we work with a handful of family-run factories in the Tuscany region to produce everything. When we started, we considered other places in Europe but ended up creating all our shoes in Italy because of the country’s long history of craftsmanship.

Can you talk a bit more about the region where Aeyde products are made?

So there are four main regions in Italy that specialize in producing shoes: Veneto, Le Marche, Naples and Tuscany. We actually started creating shoes in Le Marche but migrated everything to Tuscany one-and-a-half years ago. Due to the economic crisis in 2008, many factories had to shut down but, over the years, the factories in Tuscany have remained. The region is home to some of the best artisans working with leather in the world, so it was an easy decision for us to work with the manufacturers there. We’re also launching a jewellery line later this year that will be made in Italy.

Any tips for fashion-lovers on how to become more conscientious shoppers?

The ‘buy less and buy better’ mindset has always been a foundational part of the brand. We encourage people to invest in good quality pieces that can become long-term wardrobe staples. So for instance, instead of buying 20 pairs of shoes in a year, perhaps you can focus on buying four pairs that can be worn at many different occasions.

Another thing is to inform yourself about a brand’s supply chain and manufacturing practices. The online world has changed the information flow so every consumer has the opportunity to read about a company, obtain information about how its products are made and be more mindful about purchases. You can even reach out directly to a brand’s customer service team to better understand those processes, if that information isn’t on the website.

Looking ahead, how do you envision Aeyde’s future?

We started out as a digital-first, direct-to-consumer brand and what really drives the brand is the digital part. Ultimately, I’m dreaming of a fully digitized selling experience that would drastically change the supply chain at each step of the way. For example, think of made-to-order. This would mean creating a collection, showing it online and the customer would be able to select which products to purchase in their size. Then, we’d make the pieces specifically for them and have it delivered within two to three weeks. This would change the way brands produce from the very beginning, preventing the situation of having leftover stock and then selling it at deep discounts. It’s worth mentioning that we produce limited quantities to go through each season without having a discount phase, if possible. There are so many technical innovations that didn’t exist a decade ago that enable fashion brands to directly connect to customers, meaning they can work together to redefine how retail works and make fashion a better place.

Another initiative we’re thinking about is finding the best cobblers in various cities to partner up with so we can offer customers quality care and repair for their Aeyde products. It comes back to this idea cherishing a product and extending its life so it can be worn time and time again.